Corrosion protection is a matter of trust. Only by carrying out all process steps meticulously can a lasting result be guaranteed. That’s why the WIEGEL corrosion protection team not only offers outstanding process quality when it comes to protecting your steel. We also carry out all the associated services with the same degree of care: from order picking to fine cleaning to thread cleaning, from pre-assembly to special packaging (e.g. for overseas) to preservation, e.g. white rust protection.

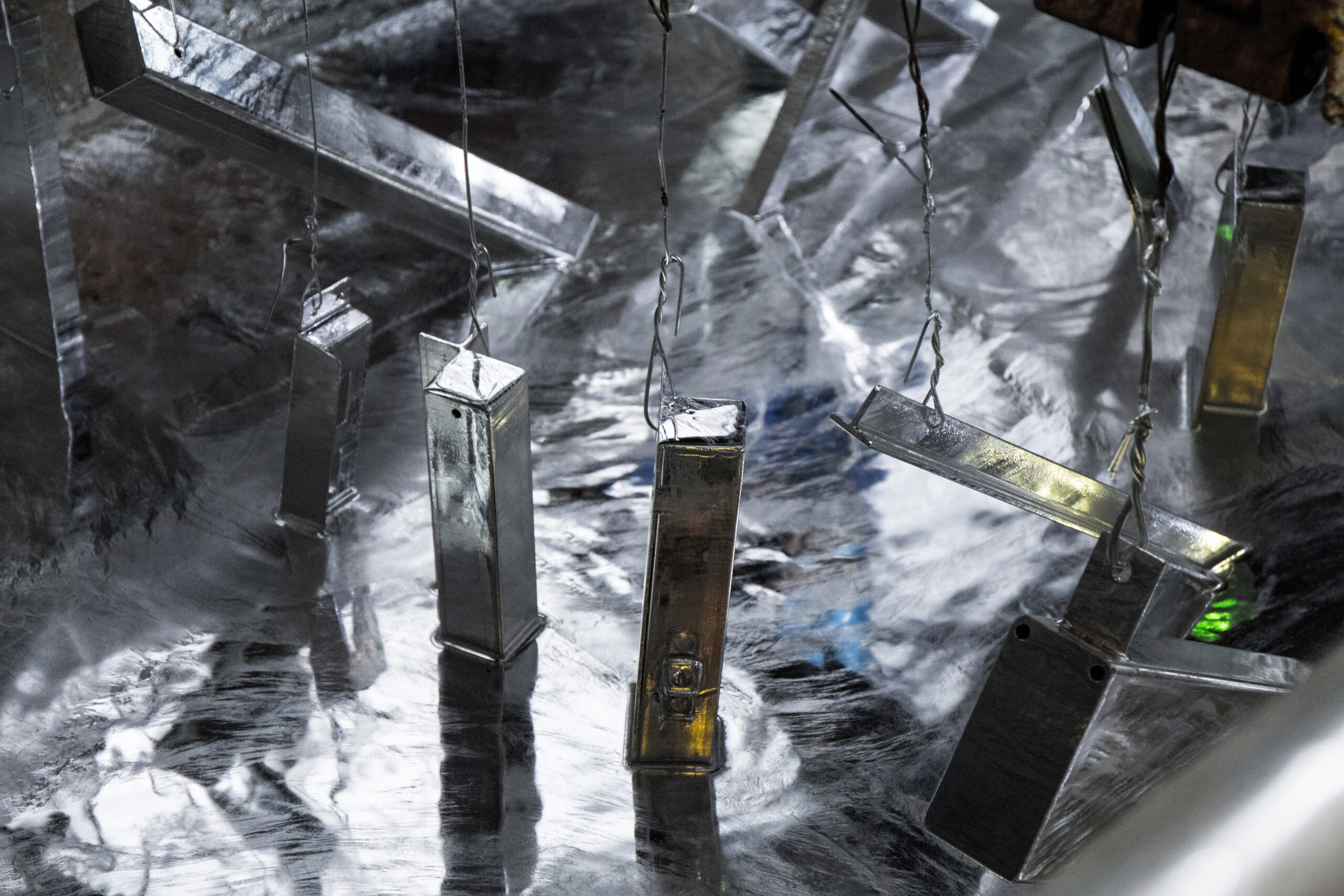

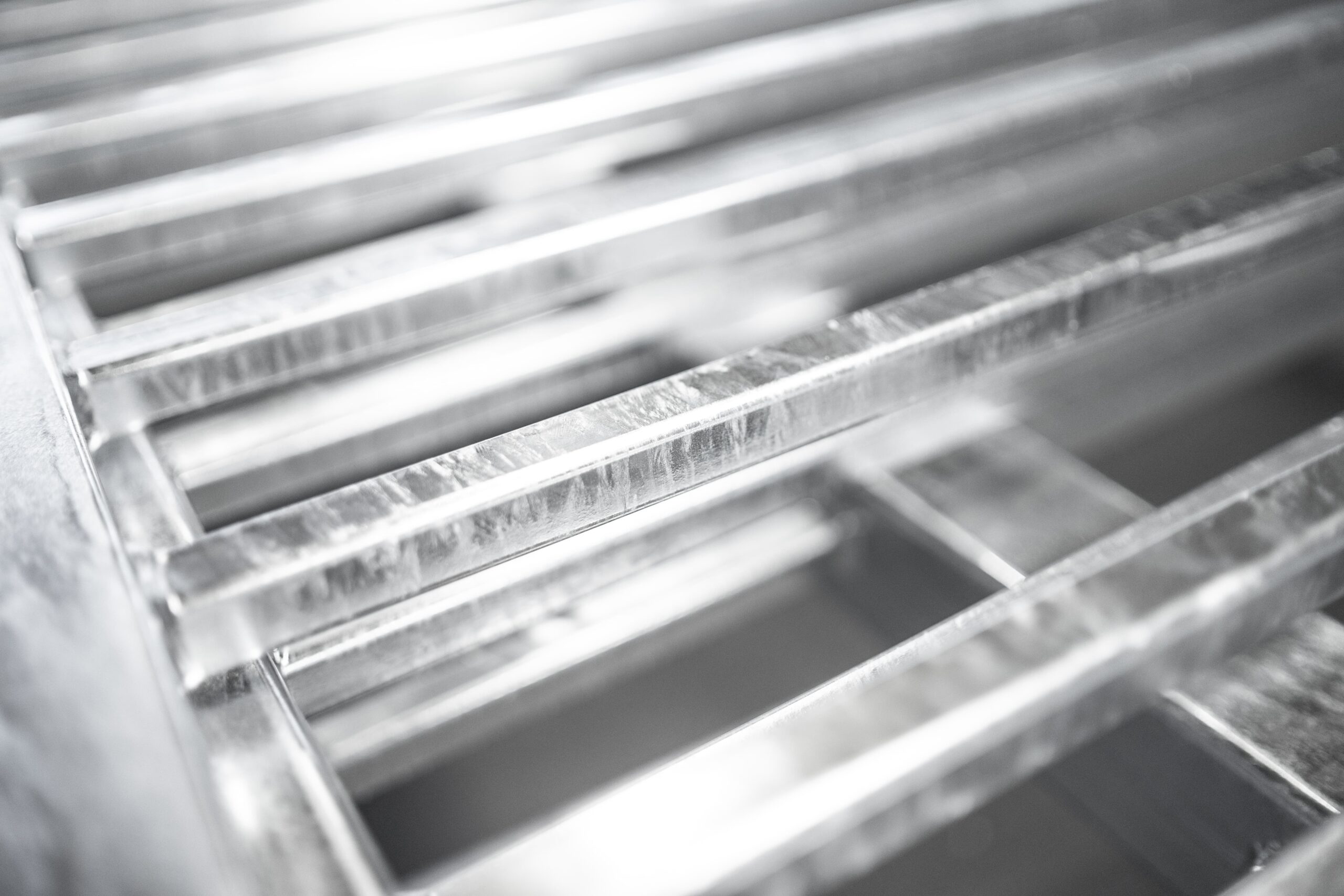

From small parts to extensive steel structures, from one-off to serial products: our hot-dip galvanising process gives your steel lasting protection against rust. Depending on the thickness of the zinc coating and the ambient conditions, we can even achieve protection periods of over 100 years.

We are always on hand to offer you expert advice on all questions relating to the optimum preparation and design of parts and relating to the DASt directive 022. The experts at WIEGEL will support you with the best classification tools and carry out the necessary magnetic particle testing in each plant themselves.

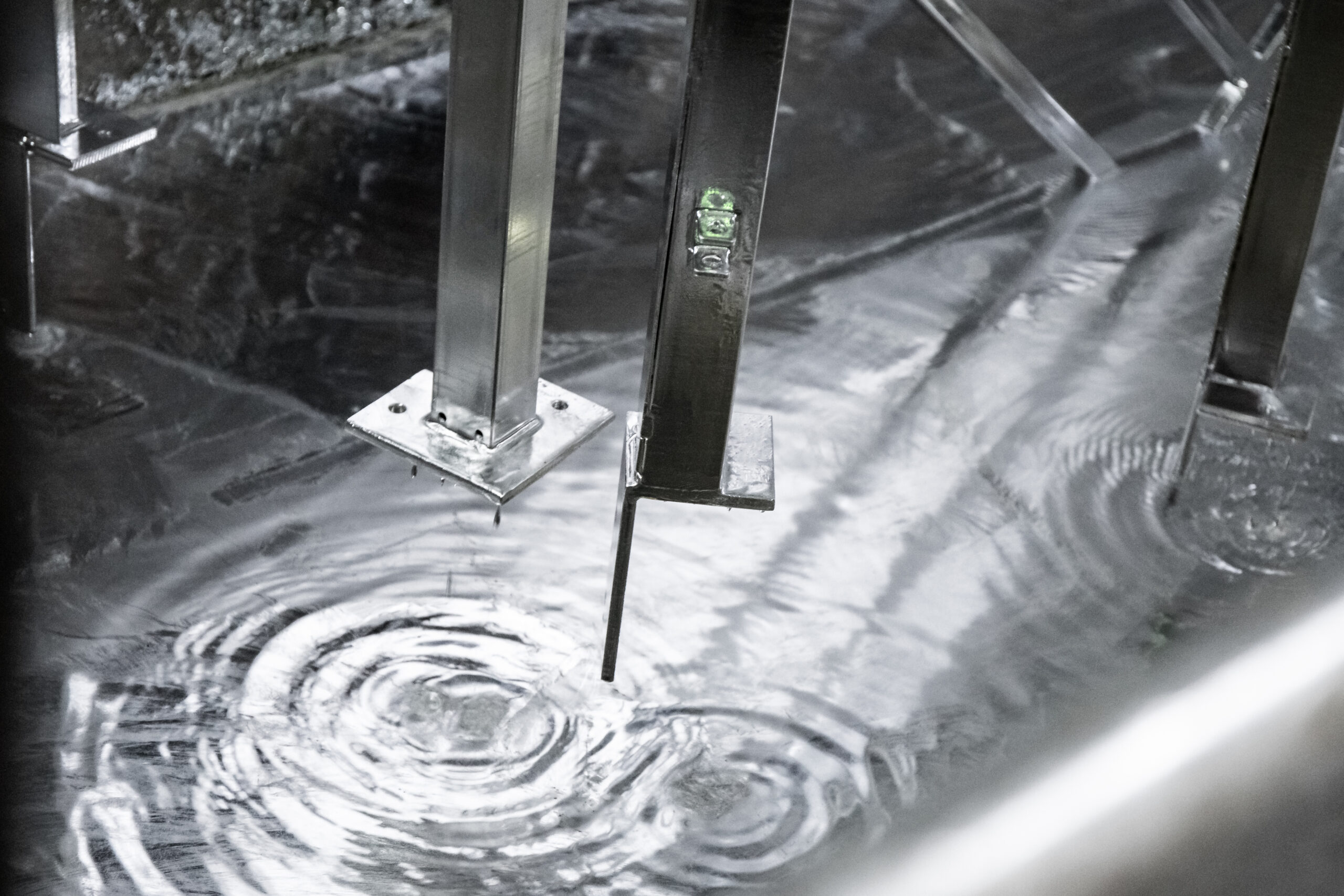

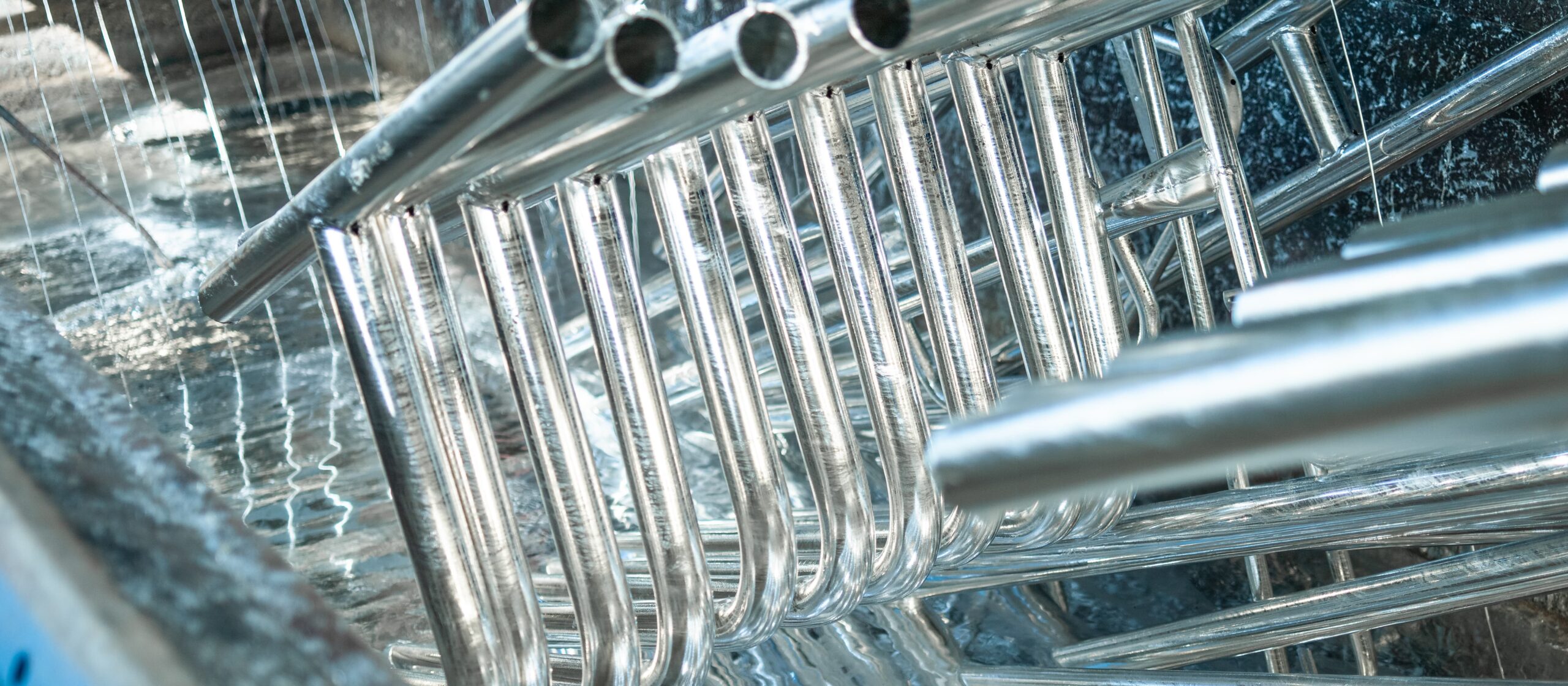

Hot-dip galvanising is a process for protecting steel parts against corrosion. In this process, the steel parts are immersed in a bath of molten zinc, which forms a corrosion-resistant coating. The process produces a metallurgical reaction in which iron and zinc form an inseparable iron-zinc alloy in the coating. Thanks to the metallurgical reaction between zinc and steel (FeZn alloy), hot-dip galvanising is the only process that provides effective long-term protection against subsurface corrosion and is even capable of sealing minor damage thanks to its cathodic protection.

Set-up

Degreasing

Pickling

Fluxing/drying

Hot-dip galvanising

It is the knowledge and experience we bring to the overall process that ultimately determine the long-term quality as well as the impact on the environment.

WIEGEL hot-dip galvanising offers efficient logistics for the collection, preparation, post-processing, order picking and delivery of your steel. We know how important it is to meet deadlines and can deliver daily or directly to the construction site, as required. Our team of experienced professionals is committed to providing first-class service that enables timely and precise delivery of your steel.